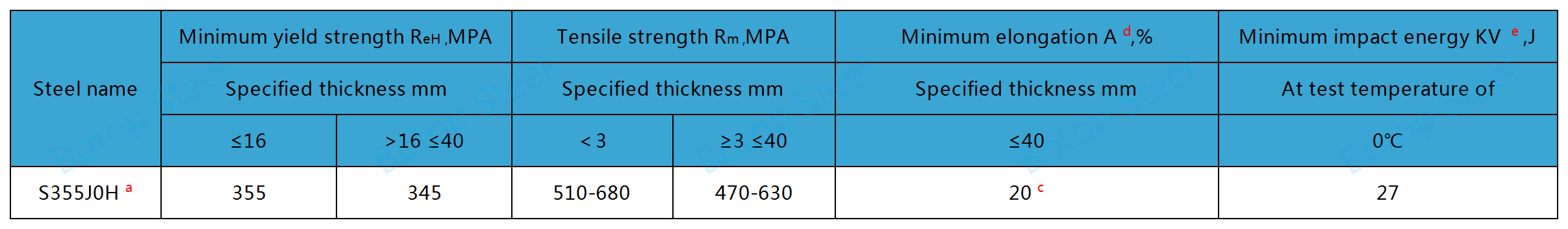

EN 10219 S355J0H is a cold-formed welded structural hollow steel pipe to EN 10219, with a minimum yield strength of 355 MPa (pipe wall thickness ≤ 16 mm) and an impact energy of at least 27 J at 0°C.

Manufactured using electric welding or submerged arc welding techniques without the need for subsequent heat treatment, they are suitable for a wide range of architectural and engineering structural applications, including critical structural components such as piles for foundation support.

BS EN 10219 is the European Standard EN 10219 adopted by the UK.

Includes cold-formed welded circular, square, rectangular, and elliptical structural hollow sections.

CFCHS = cold-formed circular hollow section;

CFRHS = cold formed square or rectangular hollow section;

We specialize in supplying high-quality circular hollow section (CHS) steel pipe to meet your various engineering needs.

Wall thickness ≤40mm;

Circular: Outer diameter up to 2500 mm;

Structural hollow sections shall be fabricated by electric welding or submerged arc welding (SAW).

EN 10219 hollow sections shall be delivered cold-formed without subsequent heat treatment, but welds may be in the welded or heat-treated condition.

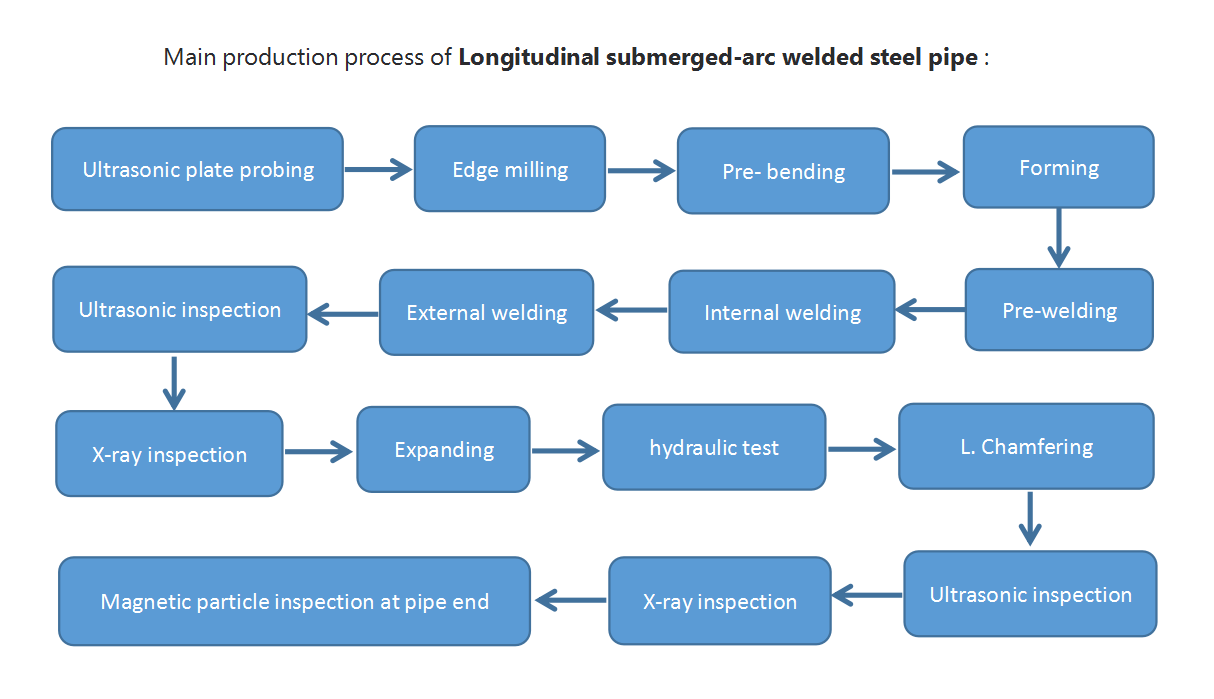

If submerged arc welding technology is used, it can be categorized into LSAW (SAWL) (Longitudinal Submerged Arc Welding) and SSAW (HSAW)(Spiral Submerged Arc Welding) depending on the direction of the weld seam.

LSAW has significant advantages in the manufacture of large-diameter and thick-walled steel pipes and is particularly suitable for application scenarios where high strength, quality, and precise dimensions are strictly required.

JCOE is a very important and representative process in the production of LSAW steel pipe. The name of the process comes from the four main steps in the pipe-making process: J-forming, C-forming, O-forming, and Expanding.

We are a high-quality welded carbon steel pipe manufacturer and supplier from China, and also a seamless steel pipe stockist, offering you a wide range of steel pipe solutions!

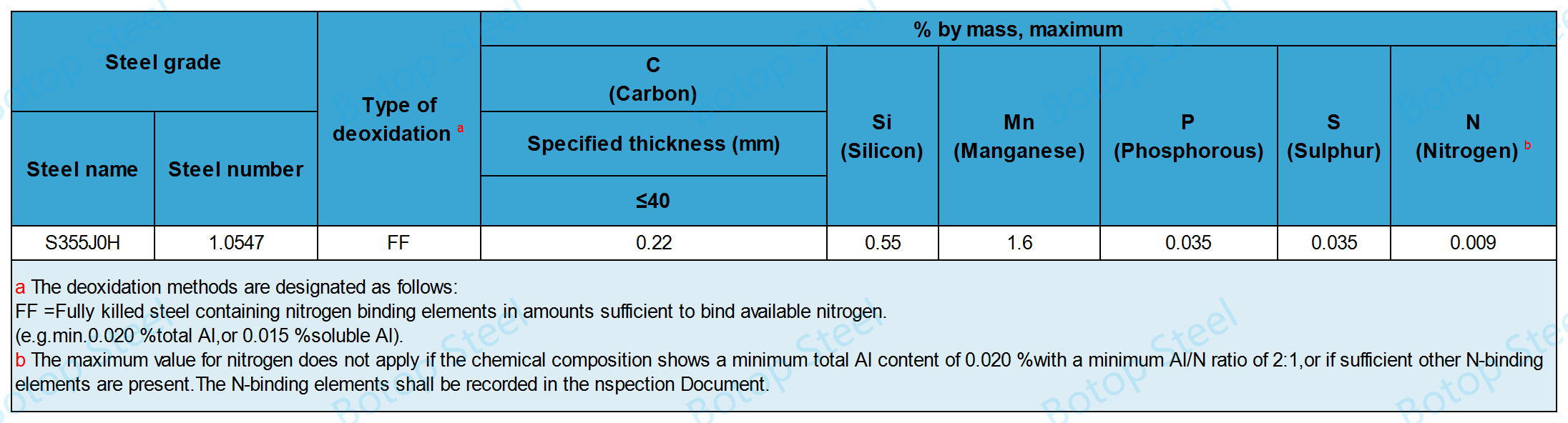

Cast Analysis

Chemical analysis of steel pipe raw materials

S355J0H Maximum carbon equivalent value(CEV): 0.45%.

CEV = C + Mn/6 +(Cr + Mo + V)/5 + (Ni + Cu)/15.

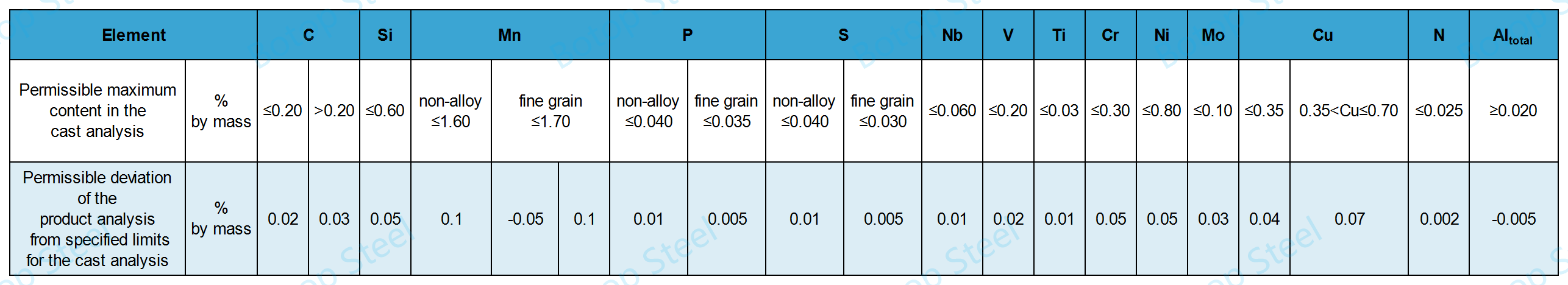

Product Analysis

Chemical composition analysis of finished hollow sections

Deviations of the product analysis from the limits specified for the casting analysis shall be in accordance with the requirements below.

Stress relief annealing at more than 580 °C or for over one hour may lead to deterioration of the mechanical properties.

The tensile test shall be carried out in accordance with EN 10002-1.

The impact test shall be carried out in accordance with EN 10045-1.

a The impact properties are verified only when Option 1.3 is specified.

c For section sizes D/T < 15 (circular) and (B+H)/2T < 12,5 (square and rectangular) the minimum elongation is reduced by 2.

d For thicknesses < 3 mm see 9.2.2.

e For impact properties for reduced section test pieces see 6.7.2.

Notes: Impact testing is not required when the specified thickness is <6mm.

Welds in submerged arc welded hollow sections shall be tested in accordance with EN 10246-9 for acceptance class U4 or radiographically in accordance with EN 10246-10 for image quality class R2.

NDT(RT) Testing

NDT(UT) Testing

Hydrostatic Testing

We use a variety of non-destructive testing techniques and hydrostatic pressure tests to ensure the strength and durability of each pipe. We provide our customers with steel pipe products that meet the highest standards of safety and quality assurance.

Hollow section tubes manufactured according to EN 10219 are weldable.

When welding, cold cracking in the weld zone is the main risk as the thickness, strength level, and CEV of the product increase. Cold cracking is caused by a combination of several factors:

high levels of diffusible hydrogen in the weld metal;

a brittle structure in the heat-affected zone;

significant tensile stress concentrations in the welded joint.

EN 10219 steel pipes are suitable for hot dip galvanizing. Selection can be made according to actual needs.

Shall have a smooth surface corresponding to the manufacturing method used; bumps, voids, or shallow longitudinal grooves resulting from the manufacturing process are permissible provided that their residual thickness is within tolerance.

Surface defects may be removed by grinding, provided that the thickness of the repaired hollow section is not less than the minimum permissible thickness specified in EN 10219-2.

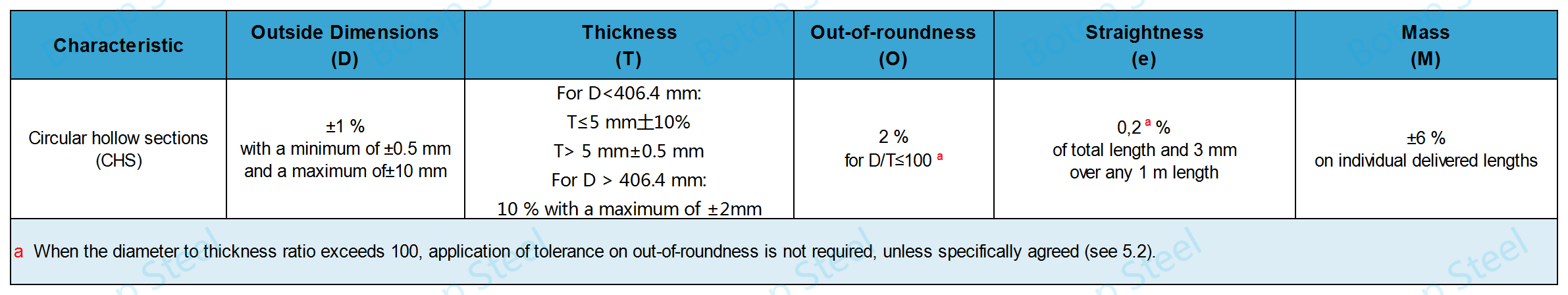

Tolerances on Shape,Straightness and Mass

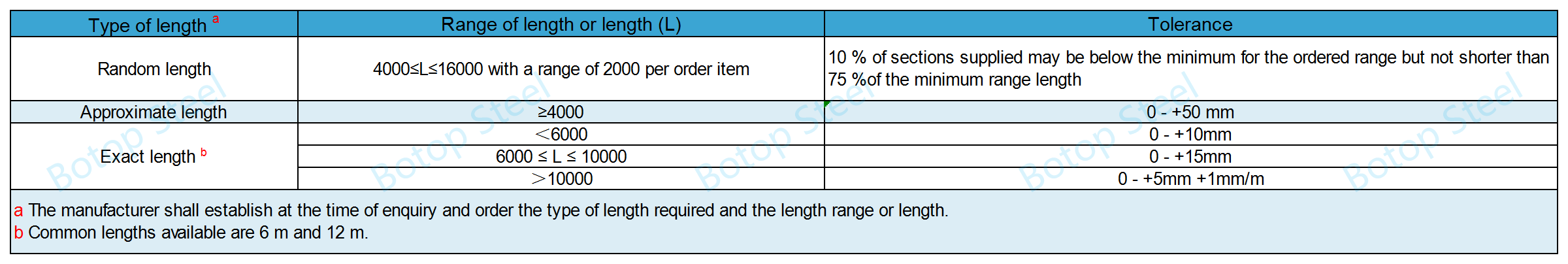

Tolerances Length

Weld Height

The weld height requirement applies only to SAW tubes.

| Thickness, mm | Maximum weld bead height, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

EN 10219 S355J0H steel pipe is a strong and corrosion-resistant material that is well suited for a wide range of building and engineering structures, including pipe pile applications.

1. Pipe Pile: S355J0H steel pipe is particularly suitable for use as foundation piles due to its strength and corrosion resistance and is widely used in the construction of wharves, bridges, building foundations, and other projects requiring deep foundations.

2. Building structures: Commonly used for components such as skeleton structures, supporting columns, and beams of buildings.

3. Pipeline transportation: It is also well suited for use as a pipeline for transporting oil and gas over long distances. However, it is usually coated to extend the service life, e.g. 3LPE, FBE, galvanized, etc.

4. Construction machinery: It can be used to manufacture brackets and parts of various construction machinery.

5. Public facilities: such as bleachers in sports stadiums and other support structures for large public facilities.

EN 10210 S355J0H: Hollow section for thermoforming welded structures. Although it is mainly used for thermoforming, its chemical composition and mechanical properties are similar to those of S355J0H and it can be used as a good equivalent material.

ASTM A500 Grade C: Used in the manufacture of welded or seamless cold-formed round, square, and rectangular tubes for structural applications. ASTM A500 Grade C provides similar yield and tensile strengths for architectural and mechanical structures.

CSA G40.21 350W: This is a Canadian Standards Association specification that covers a wide range of structural steel grades. 350W grade steel has similar yield and tensile strengths to S355J0H.

JIS G3466 STKR490: This is a square and rectangular tube material for structural use as specified in the Japanese Industrial Standard (JIS). It is suitable for building structures and mechanical purposes.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Steel Pipe

ASTM A671/A671M LSAW Steel Pipe

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Grade X70 LSAW Steel Pipe

EN10219 S355J0H Structural LSAW(JCOE) Steel Pipe